Bentofix® geosynthetic clay liners (GCLs)

Bentofix®, also known as geosynthetic clay barriers (GBR-C) are needle-punched, reinforced composites that combine two durable geotextile outer layers and a uniform core of high-swelling powder sodium bentonite clay. This forms a uniform, multi-directional, shear-resistant hydraulic barrier with self-sealing and re-healing characteristics.

Typical solutions with Bentofix®

Project advantages

Selected advantages of Bentofix®

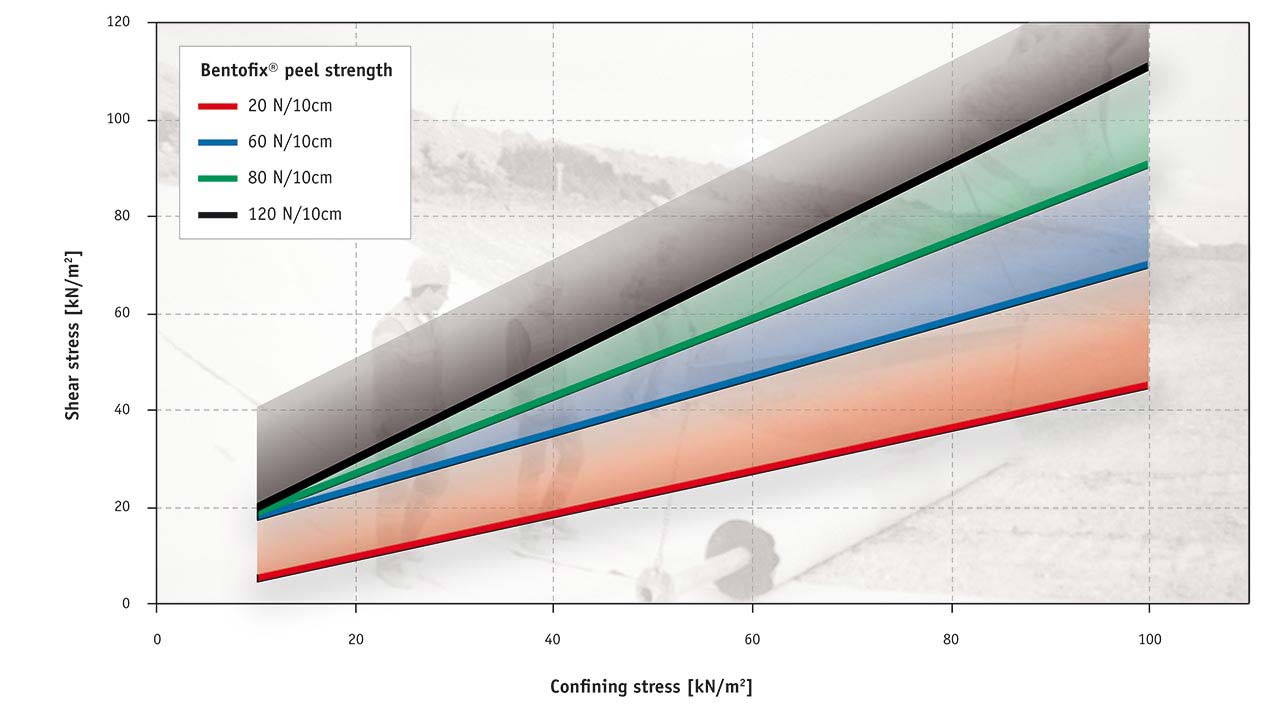

Conservative correlation of internal shear stress, dependent on the Bentofix® peel strength (hydrated under low confining stress)

Bentofix® advantage 1

Bentofix® thermal lock replaces other GCLs as well as other soil barriers on steep side slopes and assures low permeability without sacrificing slope stability.

Explanation: Bentofix® is uniformly needle-punched with over 2 million fibres/m². This results in a uniform, directionally-independent shear stress transfer. Thermal Lock additionally improves the pull-out resistance and the interface friction.

Bentofix® advantage 2

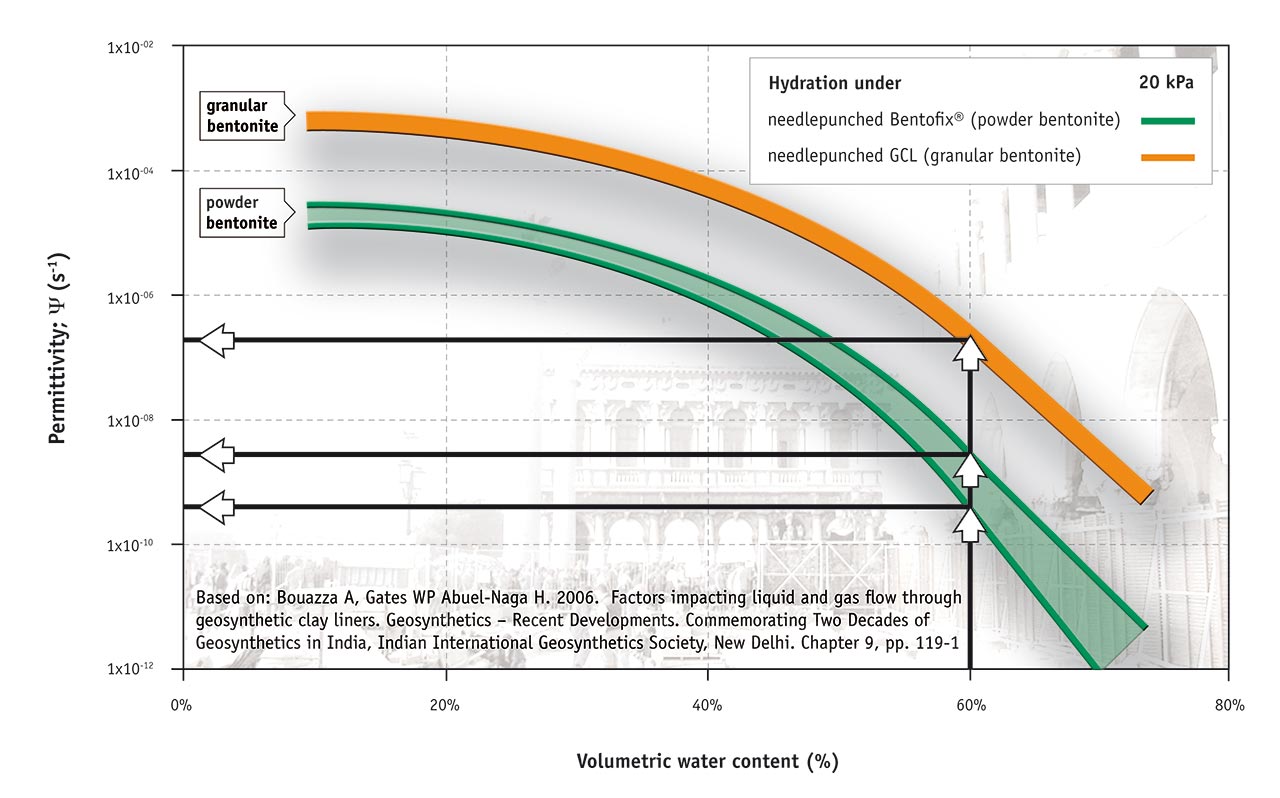

Bentofix® acts immediately as a sealing element. The explanation: high-swelling bentonite powder, uniformly distributed bentonite powder, large bentonite swelling surface and smaller air voids to close.

Performance of powdered Bentofix® bentonite compared to granular bentonite in correlation to water content and gas permittivity.

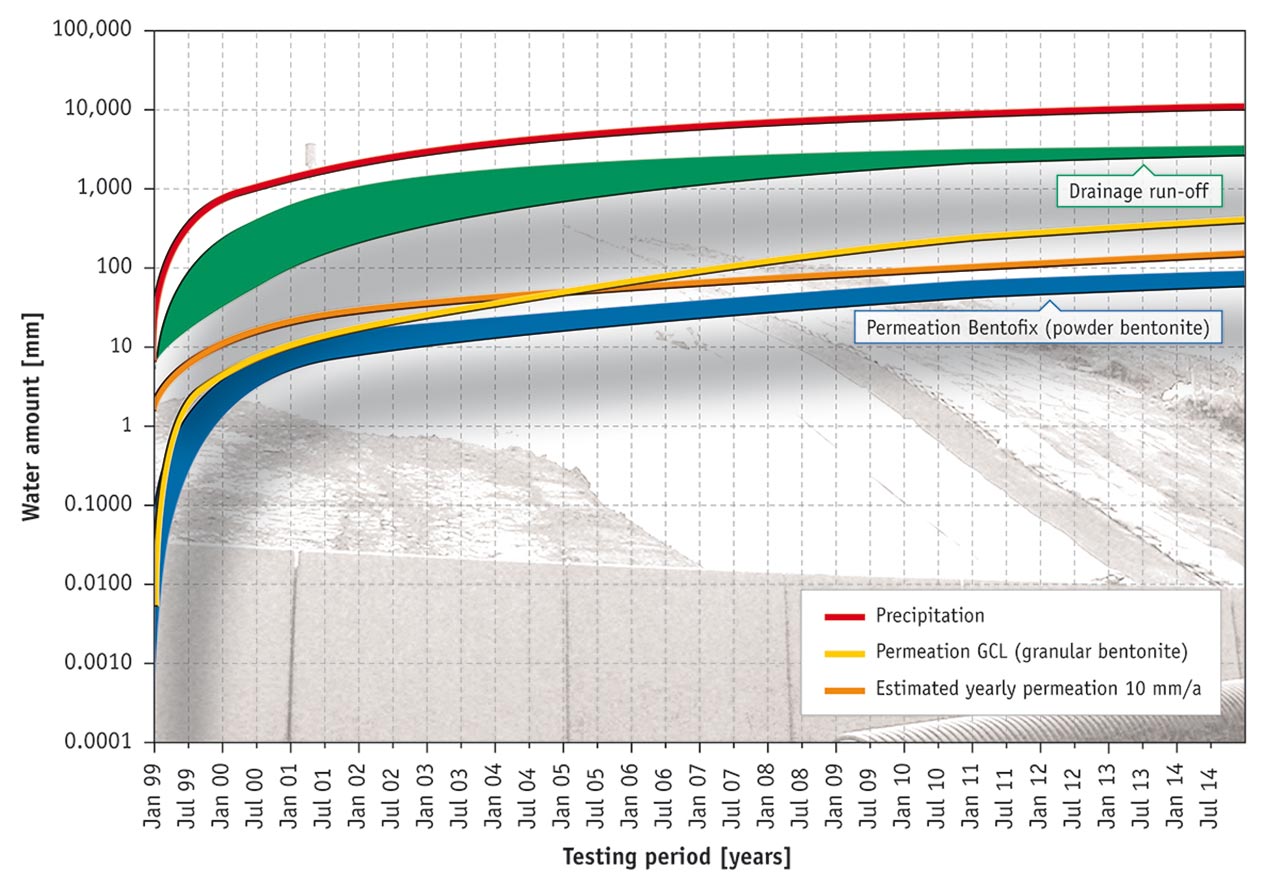

Precipitation drainage run-off and permeation values of GCLs under 1m cover soil in German climate.

Bentofix® advantage 3

Bentofix® utilises the advantages of three high-performance components in one geocomposite:

- The nonwoven protects against installation stress and increases the interface friction performance.

- The bentonite powder acts as an immediate barrier.

- The slit-film woven gives the product the dimension stability and makes the product stable for installation handling.

The result of this trio, combined with the needle-punching and Thermal Lock: A durable, low-permeable sealing system.

More geomembranes

Bentofix® X

Bentofix® X types are multicomponent geosynthetic clay liners (GCL) – also known as geosynthetic clay barriers (GBR-C).

Carbofol®

Carbofol® HDPE geomembranes are manufactured using high quality polyethylene resins.